Mesin daur ulang pelletizer / pelletizing

Aliran proses

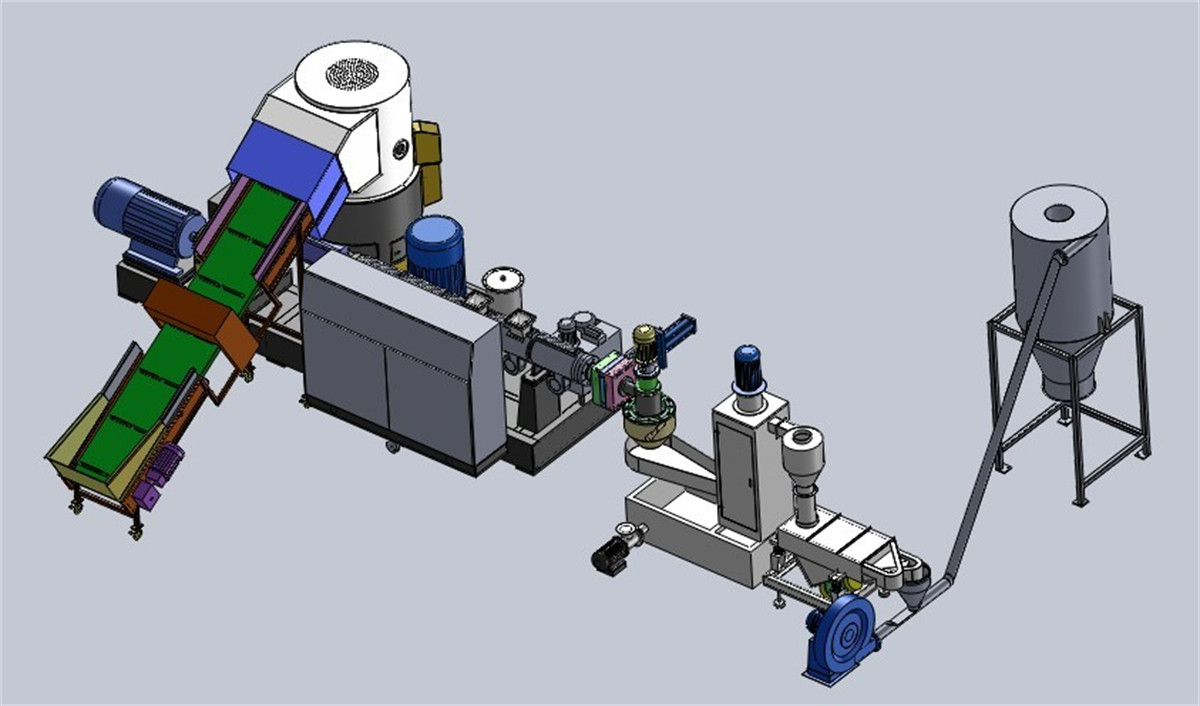

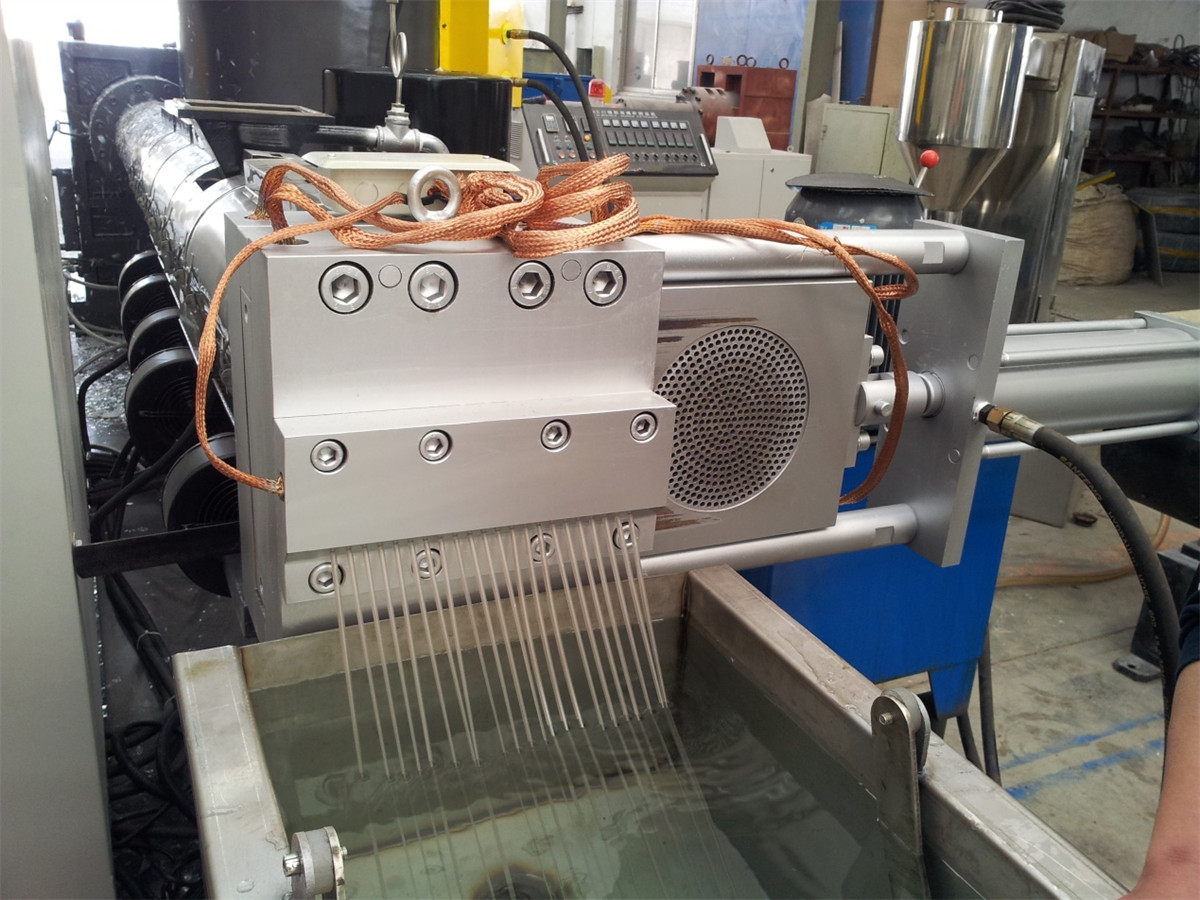

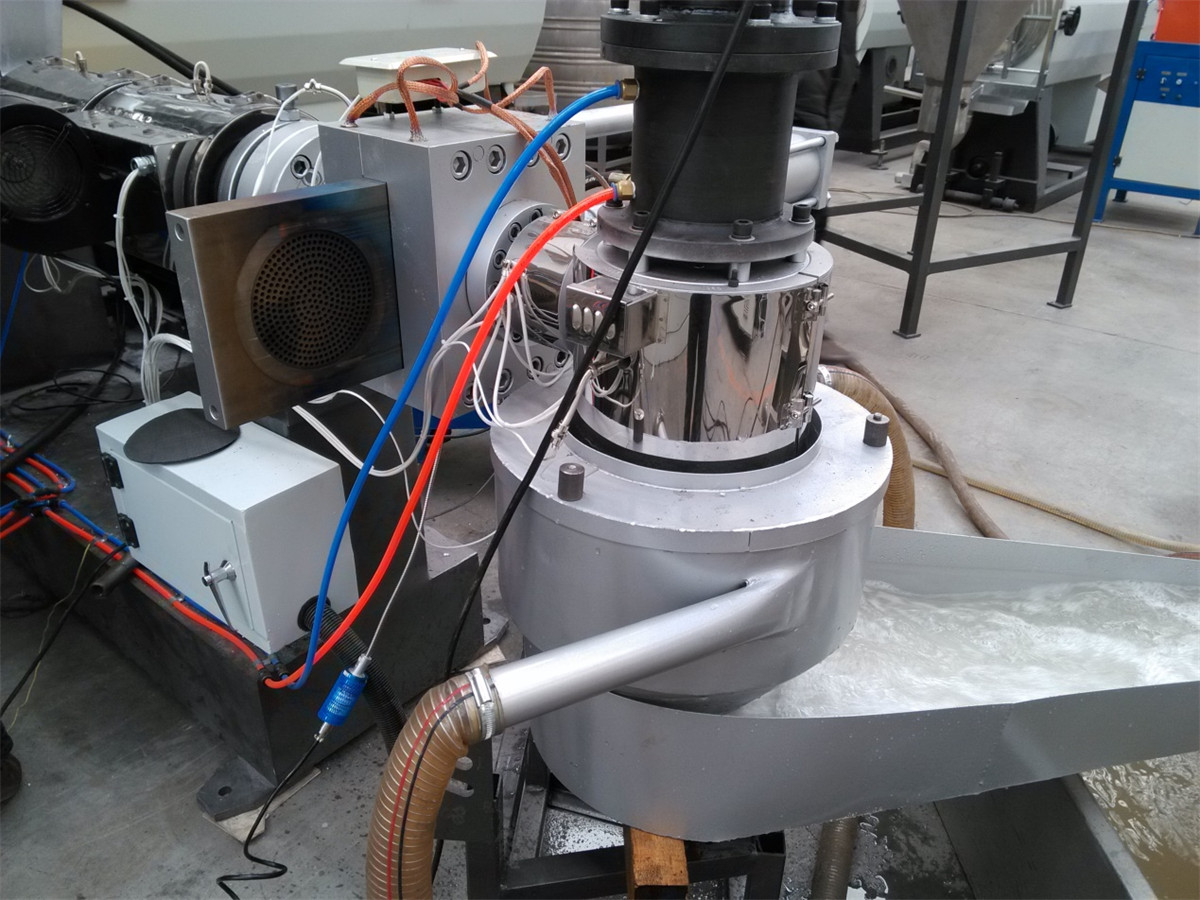

Screw feeder (OPSIONAL)→ Force feeder→1# Degassing screw extruder →1# Hydraulic filer exchanger→2# screw extruder →2# Hydraulic filer exchanger→ Mould head → Water ring cutting → Dewatering machine→ Air dryer Blowing system→ Storage hoper→ Packing produk jadi.

Kita bisa nindakake baris Produksi kanggo Granule saka ABS / PC / PP / PE / PVC / WPC miturut materi lan output kita duwe desain ngisor:

PP PE limbah film plastik daur ulang mesin pelletizing line plastik film granulator

Diagram alir garis pelletizing scraps PP/PE

Aliran proses garis pelletizing kethokan PP / PE yaiku:

Feeder sekrup → Sistem ekstrusi → Sistem pertukaran Net kecepatan tinggi → mesin pelletizing ring banyu → mesin panyerepan banyu sistem blower udara saringan kedher → Panyimpenan

200kg / jam PE / PP scraps garis Pelletizing

dhaftar produk

- 1 set crusher plastik

- 1 set feeder blower udara

- 1 set screw feeder

- 1 set feeder pasukan sisih

- 1 set mesin dosing screw feeding

- 1 set SJ100/30 Extruding Machine

- 1 set sistem ijol-ijolan Net kacepetan dhuwur

- 1 set mesin pelletizing ring banyu

- 1 set trough banyu

- 1 set mesin dewater

- 1 set ayakan geter

- 1 set sistem blower udara

Aplikasi

Jalur produksi pelletizing direklamasi kaping pindho minangka peralatan sing cocog kanggo pelletizer plastik, utamane kanggo PP, sampah film PE, HDPE, PP, BOPP, HDPE, LDPE, LLDPE, ABS, EPE, EPS, XPS, film babagan kain Non-woven, tas tenunan, bahan padhet mbalekake, Recovery materi ulig lan granulation.Ing baris produksi duwe kaluwihan saka desain novel, struktur cukup, operasi stabil, kurang gangguan, konsumsi daya kurang lan output dhuwur.